smilemaker

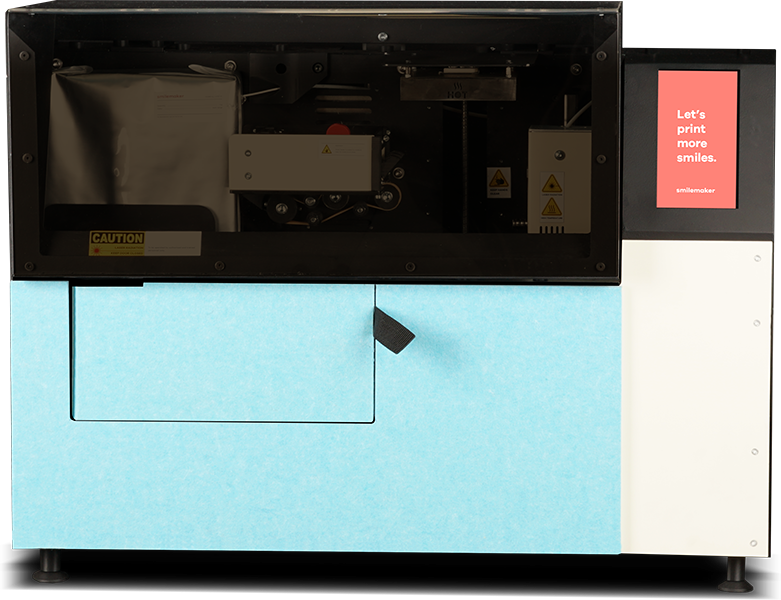

the world’s first clear aligner printer.

As seen at IDS 2025 | Available now.

Built on the patent pending AutoformingTM techology, Smilemaker turns clear aligner fabrication into an automated and 100% hands-free process.

Witness the start of a new era in clear aligner production.

A clear future ahead.

The global clear aligners market is projected to experience significant growth in the coming years, with a forecast to reach $45+ billion by 2032, market insights reports show. This growth is driven by technological advancements, increasing awareness of dental aesthetics, and a preference for discreet and comfortable orthodontic treatments.

Clear aligner orthodontics remain to be a pivotal field of dental care in the coming years.

Thermoforming:

the proven method

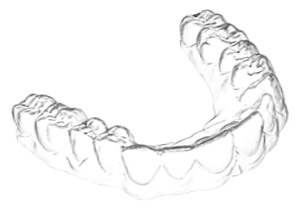

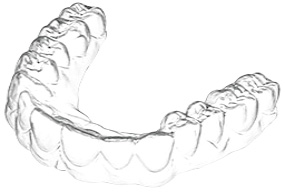

Clear aligners have been traditionally produced with aligner sheets thermoformed on 3D printed models that are representing each adjustment phase of the treatment process.

However, 3D printing the models, washing and post-curing them, thermoforming, trimming and polishing each aligner is a meticulous process that requires a lot of manual labour.

PROS:

- Proven and tested for 25 years across 10+ million cases

CONS:

- Many labour intensive steps in the production process

- Automation exists on industrial scale only

Direct printed aligners:

an uncertain revolution

Resins for the direct 3D printing of clear aligners have been designed to simplify the aligner production process, but they created nearly as many new challenges as they solved.

The process still needs manual care, post-curing requires special equipments and aligner resins are nowhere near as reputable materials as thermo- plastic aligner sheets.

PROS:

- Alternative to the thermoforming method, less steps

CONS:

- Not enough case history

- Support removal, washing and curing are still manual steps

- Special post-curing equipment is a must

- Cytotoxicity is a thing

5 years in, aligner resins are only a tiny fraction of the aligner market owing to their strong limitations.

It’s time for a different path.

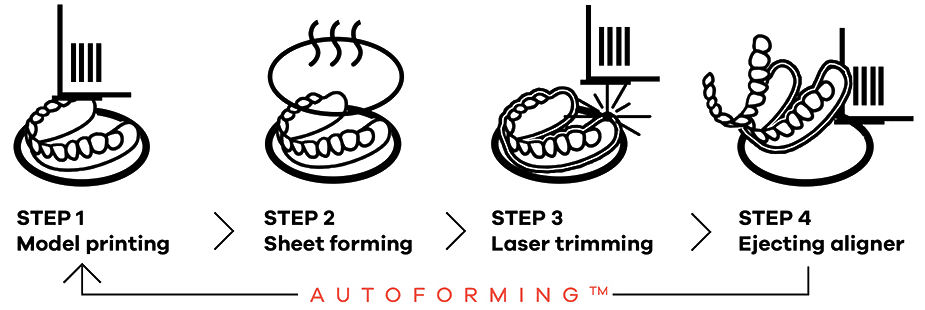

New technology: AutoformingTM

Autoforming overcomes the greatest shortages of clear aligner production by enabling a 100% automated and hands-free process.

Instead of using direct aligner resins, AutoformingTM takes the conventional thermoforming process that has been proven across millions of cases globally and fully automates it in a benchtop-sized machine called the Smilemaker.

Why is AutoformingTM superior to conventional thermoforming or direct aligner resins?

24/7 unattended production

of great quality clear aligners

Lowest per aligner costs

due to the elimination of all manual labour

Benchtop size & safe to install

in any indoors location

smilemaker

Your aligner factory on the benchtop.

Smilemaker uses a specialty filament material to print each aligner on a circular platform. This enables a fully automated and hands-free process. Trimming is performed by a high power laser with great precision and smooth edges.

Smilemaker is everything you need to sit back and relax while your clear aligner factory is ramping up production, right on your benchtop.

- Compatible with all major ortho planner software

- Accepts open STL models and PTS trimline (both scalloped and straight)

- Laser trimming with great smooth edges

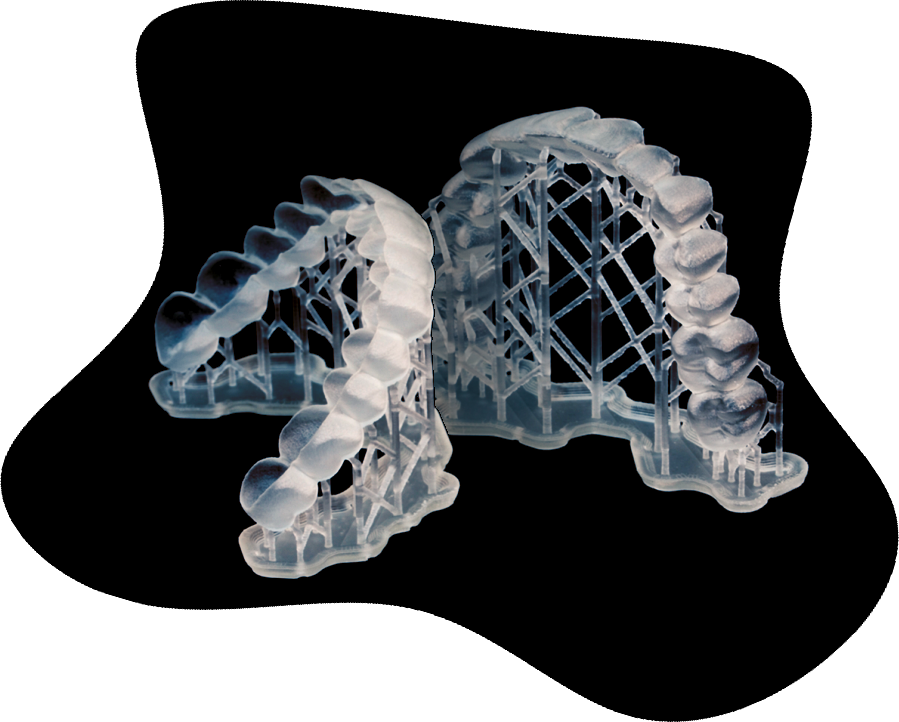

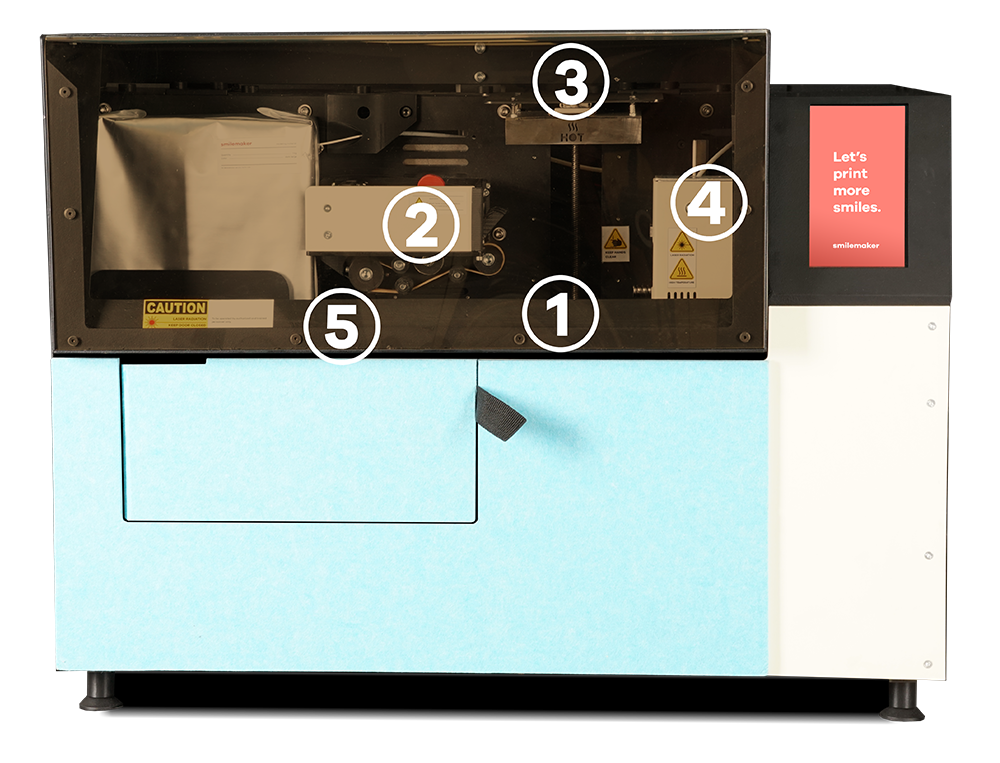

Smilemaker’s AutoformingTM process consists of 5 fully automated steps.

1

Model printing

Printing of the aligner model on the main platform

2

Sheet loading

Moving of the sheet blanks to heating position

3

Sheet forming

Heating of the sheet, thermoforming on the model

4

Laser trimming

Trimming of the aligner based on the trimline file

5

Ejecting

Ejecting of the sheet and model with the cut aligner on top

Comparison

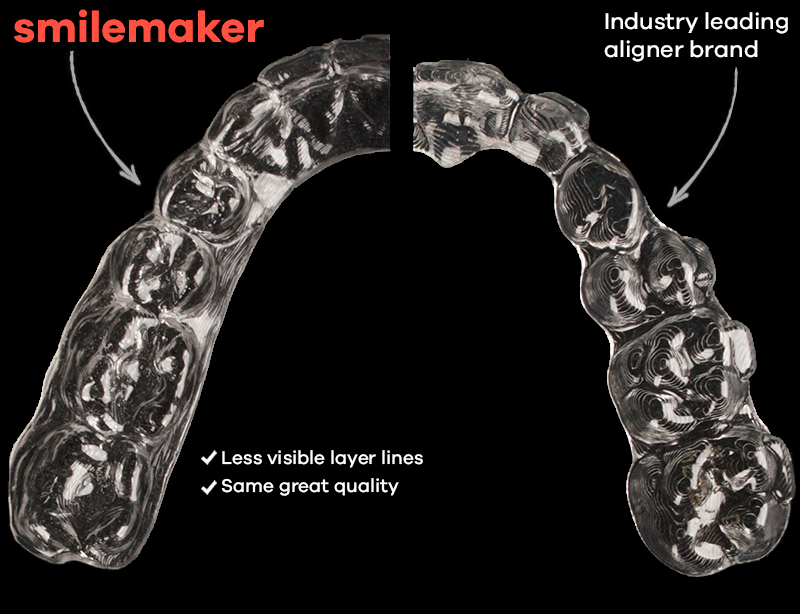

Smilemaker produces quality aligners comparable to industry-leading brands.

Save up to

90%

on your production costs

Model costs less than €1 each

Standard blank sheets of 120 or 125mm

No polishing or aftertouching in most cases

Produce great quality aligners at a fraction of the cost.

Produce

24/7

for a rapid ROI of your Smilemaker

Print up to a full case in less than a day

Unattended and 100% hands free production

Easy to learn and delegate

Orthodontic design in the cloud

The new Smilemaker printer blends seamlessly into the VOXELTEK digital dental ecosystem. The VOXEL.IOS intraoral scanner takes beautiful detailed patient scans in just a few minutes, while our orthodontic design services are available to anyone over the VOXELTEK.live online CAD platform.

VOXELTEK is your one-stop provider for clear aligner technology hardware and services

VOXELTEK.live is a great platform to back you up on clear aligner case design.

New horizons ahead

Thanks to our online ortho CAD planning services and the 100% hands free operation of the Smilemaker printer, aligner production is no longer a thing of dental labs, clinics or specialty factories.

Smilemaker is ready to be installed in hospitals, health houses, community centres and schools, bringing clear aligner orthodontics closer to millions of people around the globe and opening an exciting new chapter in digital orthodontics.

Democratizing the world of clear aligners.

There is such a difference clear aligners can bring to people’s lives. Smilemaker clear aligners do not only live up to the highest esthetical standards, but are by far the least expensive means of clear aligner production.

Clear aligners have helped over 10 million people by improving their oral health, self-esteem and confidence.

Now it’s time to improve the life of many millions more by bringing inexpensive and great quality Smilemaker clear aligner orthodontics to them. This is the mission of the new AutoformingTM technology.

Our mission

At VOXELTEK, we have been passionate about serving tech-savvy technicians and doctors around the globe since the introduction of our first desktop dental 3D printer in 2016. Since then, we never ceased to innovate and now it’s time we revolutionized the world of dental clear aligners with the introduction of our new AutoformingTM technology.

Contact Us

To inquire about our groundbreaking AutoformingTM technology or our Smilemaker clear aligner printer, please get in touch. Let’s explore together how we could elevate your dental business.

Frequently Asked Questions

Why is AutoformingTM such a big deal?

Thermoforming has been superior technology for the production of clear aligners. Complete automation has been a privilege to large production companies through industrial-scale machinery. AutoformingTM enables the smallest dental labs or clinics to produce their own great quality clear aligners with zero manual work or experteese on model printing, thermoforming or trimming.

Why is filament material used for model printing?

Photopolymer resins are generally considered ideal for aligner model printing, however multiple different technologies work too, such as SLS or filament-based printing. While resin printing is very difficult to automate because of the neccessary post-processing steps, filament-based printing can be performed in an autonomous machine and this is exactly what our patent-pending AutoformingTM technology does. Layer resolutions of the Smilemaker clear aligner printer are comparable to industy-leading brands.

As I heard, direct aligner resins are the future of aligner production. Do you disagree?

We disagree. Aligner resins have been on the market for nearly 5 years now, however the number of aligners produced this way is virtually undetectable compared to all clear aligners. This is simply because the process is not easy enough, there’s a lot of trial and error and there are a small number of documented treatments to prove that direct printed aligners even work as intended. On the contrary to that, Smilemaker’s Autoforming uses the conventional thermoforming method that has been proven through millions of cases, only in a fully automated compact machine.

Can I have my own Smilemaker clear aligner printer?

Absolutely. After years in the making, Smilemaker has finally been released at the IDS 2025 show in Cologne, Germany. As of spring 2025, Smilemaker is available for orders. Inquire for pricing and details on shipping and installation.